Marking Solutions for the Automotive Industry

Efficient Automation for Permanent Automotive Marking

Typical Marking Applications

MECCO’s portfolio of Laser and Dot Peen technology supports a wide range of Automotive applications, delivering permanent marks on diverse materials. Key applications include:See videos showcasing MECCO's automotive applications.

Common Automotive Materials

Our systems excel at marking the most common automotive materials, ensuring durability and legibility for traceability, assembly, and maintenance. Key materials include:• Steel and Stainless Steel: For chassis, engine components, and suspension arms.

• Aluminum and Anodized Aluminum: Lightweight components for EV battery housings to engine mounts.

• Polycarbonate and ABS: Interior trim to electronic housings.

• Nylon and Polypropylene: Connectors, bumpers, and under-hood parts.

• Glass and Composites: Windows, mirrors, sensors, to carbon fiber parts for high-performance vehicles.

Automotive Industry Certifications

Premier Marking Solutions for Automotive

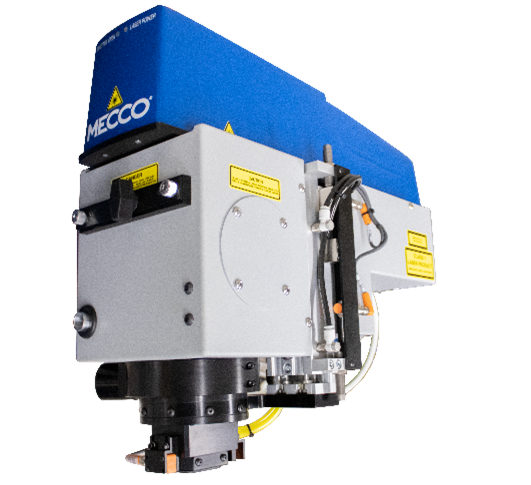

200W SMARTmark® VP MOPA Fiber Laser Marking Machine

Learn About SMARTmark® VP MOPA Fiber lasers

Scribe Marking System

Sealed Class I Laser Marking System

Mark large automotive parts safely and efficiently with the SMARTmark® Safety Seal Enclosure, the first and patented, CDRH-approved Class 1 laser sealing system. This compact solution can be integrated into automated cells or used in manual workstations with a gravity-arm.

• Safe and Compact: Eliminates bulky safety enclosures and creates a Class I laser safe environment using the part.

• Flexible Configurations: Custom seals for marking different materials and geometries.

Learn more about the SMARTmark® Safety Seal Enclosure

Four Position Rotary System

Maximize productivity with the Four-Position Rotary Workstation, designed for simultaneous laser marking, loading, and unloading. Streamline multiple processes by incorporating pre-mark vision, post-mark inspection, and various custom options. This machine utilizes a SMARTmark Fiber marking system to produce high-contrast, backlit marks on glass.

Success Story

MECCO’s patented SmartMark® 20W Fiber Laser with Safety Seal powers Ford’s Michigan transmission plant by engraving 2D Data Matrix and human-readable codes on transmission cases at various production stages. Ford selected MECCO for its cost-effective, compact design and enhanced safety, reducing the need for extensive guarding. The Safety Seal provides light-tight protection for high-speed, automated marking, ensuring traceability and warranty tracking. This system integrates easily into assembly lines, making it ideal for automating data creation for automotive parts.

Request a Quote

Looking to implement one of our marking solutions for automotive manufacturing? Fill out this form to request a system quote, and we'll get back to you to discuss your project requirements.

CASE STUDY: Automotive

Ford Motor Co.

MECCO developed a revolutionary new method for safely using a laser to mark large automotive parts. This new patented technology is helping a number of companies like Ford Motor Company’s Livonia, Mich., transmission plant to integrate a safe laser marker into their existing production line.

MECCO RESOURCES

We're used to tackling manufacturers' challenges across various industries. Take a look at some of the systems we've built to help streamline marking and traceability.

Latest News

-

How to Maintain Your Dot Peen Marking Machine for a Longer Life

Read MoreDot peen marking machines are typically considered durable and built to last. Regular maintenance is essential for extending its l...

-

How Laser Marking Reduces Operational Costs for Manufacturers

Read MoreIn today’s competitive manufacturing environment, efficiency matters. One technology helping manufacturers meet this challenge hea...