Marking Solutions for the Fabrication Industry

Produce the Deepest Mark in the Industry

Additionally, MECCO delivers integrated laser and dot peen traceability systems to facilitate the marking of fabricated components, ensuring that each item is effectively identifiable and traceable throughout the entire production and supply chain. This commitment to innovative solutions allows fabricators to enhance their operational efficiency while upholding the highest standards of safety.

Why Choose MECCO?

- Readable Depth: Produce a legible mark every time with the portable COUTH N-34 Series: readable after painting, galvanizing, or plating.

- Seamless Integration: Compact, versatile laser and dot peen systems designed to fit effortlessly into existing manufacturing floors.

- Durable Equipment: Our COUTH dot peen marking systems are heavy-duty machines specifically intended for deep marking applications.

- Handheld Marking: Easy-to-use portable marking systems offer the ability to mark large parts or mark in the field.

Typical Marking Applications

MECCO’s portfolio of laser and dot peen technology supports a wide range of fabrication applications, delivering permanent marks on diverse materials. Key applications include:

- Serial and Batch Number Engraving: Fastest, Deepest Dot Peen, Scribe and Laser marking that exists

- Data Matrix Codes: AIM DPM 2D codes on materials for cradle-to-grave tracking

- Track and Trace Marks: Serial and batch numbers on casting and forgings for supply chain efficiency

- Bend Line Information and Special Instructions: Mark Cut, bend, or other manufacturing marks on the product directly

- Branding and Logos: High-resolution marks on metal and plastic parts for brand consistency

Common Fabrication Materials

Our systems excel at marking the most common automotive materials, ensuring durability and legibility for traceability, assembly, and maintenance. Key materials include:

-

Steel and Stainless Steel

-

Aluminum and Anodized Aluminum

-

Brass

-

Copper

-

Titanium

-

Iron

Industry Certifications

MECCO’s solutions are engineered to meet rigorous industry standards:

- ODVA Membership: Ensuring compatibility with automation protocols.

- CE Certified: Meeting global safety and performance requirements.

Learn more about MECCO’s certifications.

Marking Solutions for Fabrication

N-34 Deep Marking Machine

The N-34 Dot Peen Marker is a heavy-duty machine designed for deep marking of structural steel and other metals. It ensures part traceability and maintains readability even after painting or plating. With a flexible marking head that operates in any position, the N-34 offers great portability for marking large parts.

Learn About Deep Marking Machines

Flange Marker

The Flange Marking System, previously known as MC2000, is an advanced dot peen marker that uses impact pin marking technology with a precision rotary chuck. It marks various pipes, couplings, and other round parts with adjustable features for different diameters and weights. The marking head easily slides for quick size changes, and a heavy-duty adjustable chuck is mounted on a sturdy steel base.

Learn About Flange Marking

SuperFast Marking Machine

The Couth SuperFast, formerly MC2000, is a next-gen dot peen marker that uses Vibra Peen™ technology to pulse the pin 80 times per second, creating solid characters. This results in high-quality marks similar to engravings. By combining this technology with a patented Y-axis pivot system, manufacturers can achieve better marks in half the time.

Learn more about SuperFast Marking

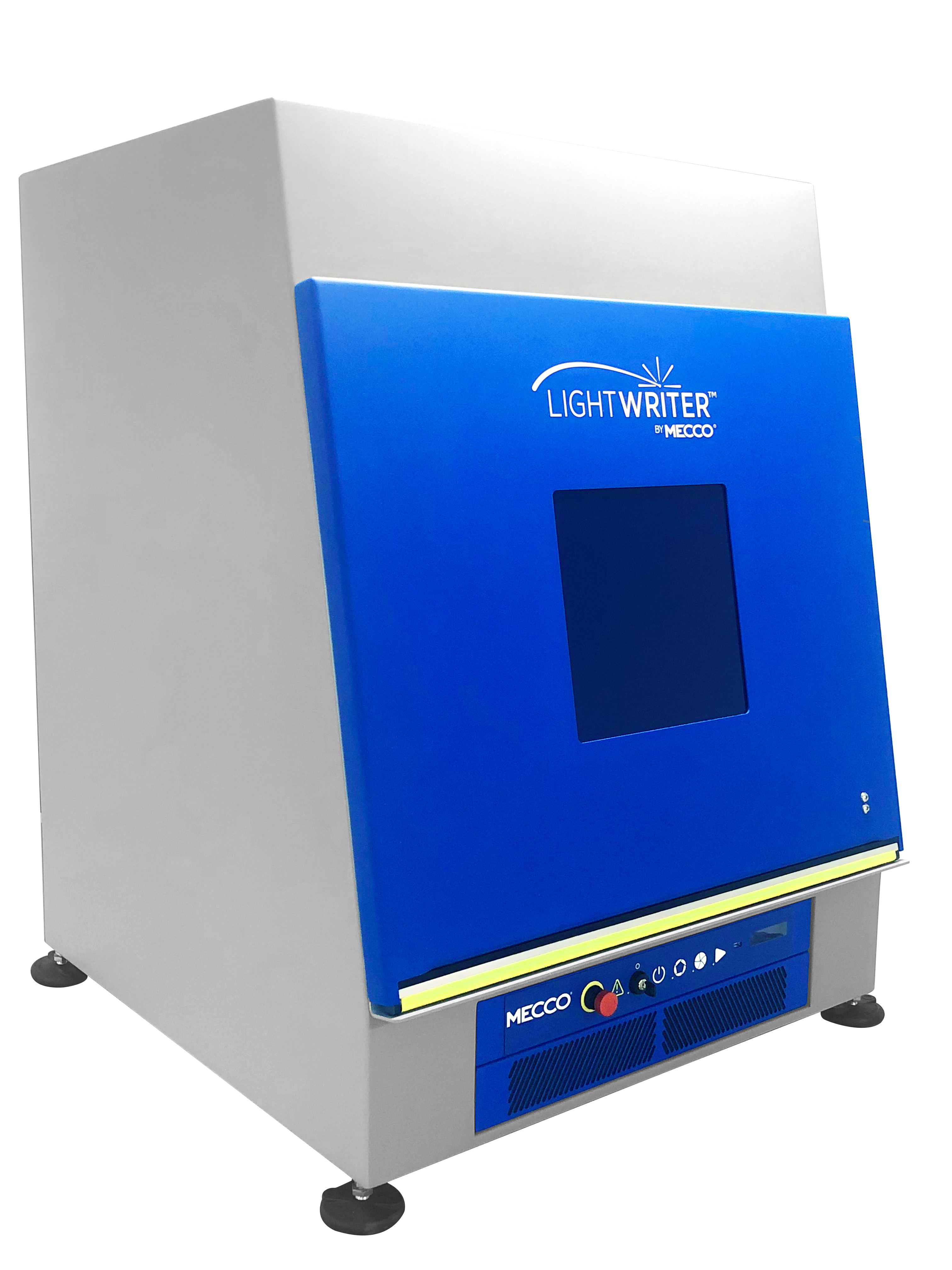

LightWriter Class I Marking System

Mark a large range of manufactured components safely and efficiently with the LightWriter Class I Marking System. The LightWriter seamlessly integrates into your existing database and is straightforward for operators to learn and use. Transform your marking process with our cutting-edge solution that includes WinLase software. Class IV options are also available for easy integration and marking of oversized parts.

Learn more about the LightWriter™

Success Story

Hilite's Northern Stamping division specializes in precision-stamped and welded components for automotive OEMs and Tier 1 suppliers, focusing on medium to large stampings with tight tolerances. Utilizing advanced metal stamping technologies and robotic welding, part identification and traceability are crucial for achieving zero defects. MECCO’s COUTH SuperFast dot peen markers are employed at inspection stations to mark parts with traceability information after passing quality tests. Some parts also feature a 2D Data Matrix for assembly sequencing.

Hilite needed to mark 2D Data Matrix codes on components like crossmembers and trailer hitches, ensuring the marks remained readable even after e-coating. The rugged COUTH SuperFast system with the N20 marking head was implemented, resulting in increased productivity from high-speed marking and durable dark marks.

Deepest Marks Made FastProduce a legible mark every time with the portable COUTH N-34 Series: readable after painting, galvanizing or plating.

Durable EquipmentOur COUTH dot peen marking systems are heavy duty machines specifically intended for deep marking applications.

Hand Held MarkingEasy-to-use portable marking systems offer the ability to mark large parts or mark in the field.

|

Request a Quote

CASE STUDY: Fabrication

Walkup Company

Striving to be one of the premier fabricators in the southwestern United States, Walkup Co. was in search of a new marking system to replace the costly, inefficient, and unsafe hand stamp process they used for oil field part traceability. Their customers include large corporations that have rigorous quality control standards, and they expect a high level of quality from their vendors. Learn how they increased quality and reduced injuries.

MECCO RESOURCES

We're used to tackling manufacturers' challenges across various industries. Take a look at some of the systems we've built to help streamline marking and traceability.

Latest News

-

How to Maintain Your Dot Peen Marking Machine for a Longer Life

Read MoreDot peen marking machines are typically considered durable and built to last. Regular maintenance is essential for extending its l...

-

How Laser Marking Reduces Operational Costs for Manufacturers

Read MoreIn today’s competitive manufacturing environment, efficiency matters. One technology helping manufacturers meet this challenge hea...