Blog

Dot peen marking machines are typically considered durable and built to last. Nevertheless, just like any equipment, regular maintenance is essential to extending its lifespan and making sure it functions properly.

Designed to operate in industrial environments, dot peen marking machines are used to make deep, clean marks on a variety of materials. But over time, even the sturdiest machines can break down without the right care. In this article, we’ll walk through vital maintenance practices to extend the life of your dot peen system and keep your operations running smoothly.

Common Maintenance Challenges for Dot Peen Machines

The number one maintenance issue we see with dot peen marking machines is simple neglect. Oftentimes this equipment has been in use for several years and has taken a beating, just like any tool in an industrial facility.

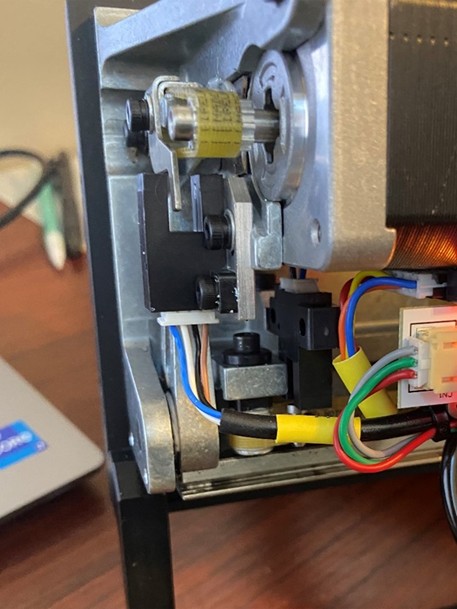

These machines often operate in dirty environments such as metal mills, heavy fabrication shops, or dusty warehouse floors. Without regular cleaning and inspection, dust and debris can cause serious internal damage. Motors can jam. Belts can break. Photocells can fail. We’ve seen machines with cut cables, broken air lines, and worn-down rings due to a lack of basic preventative maintenance.

Handheld dot peen machines are more susceptible to damage than mounted versions because operators move them around a lot – meaning they’re more likely to be dropped, banged, and exposed to contaminants.

What Proper Maintenance Looks Like

Maintaining a dot peen machine is fairly straightforward, but it does require consistency. Here are the key steps to include in your routine:

- Lubricate air cylinders regularly to prevent them from drying out.

- Inspect rings, photocells, and air lines for wear, dirt, or cracks.

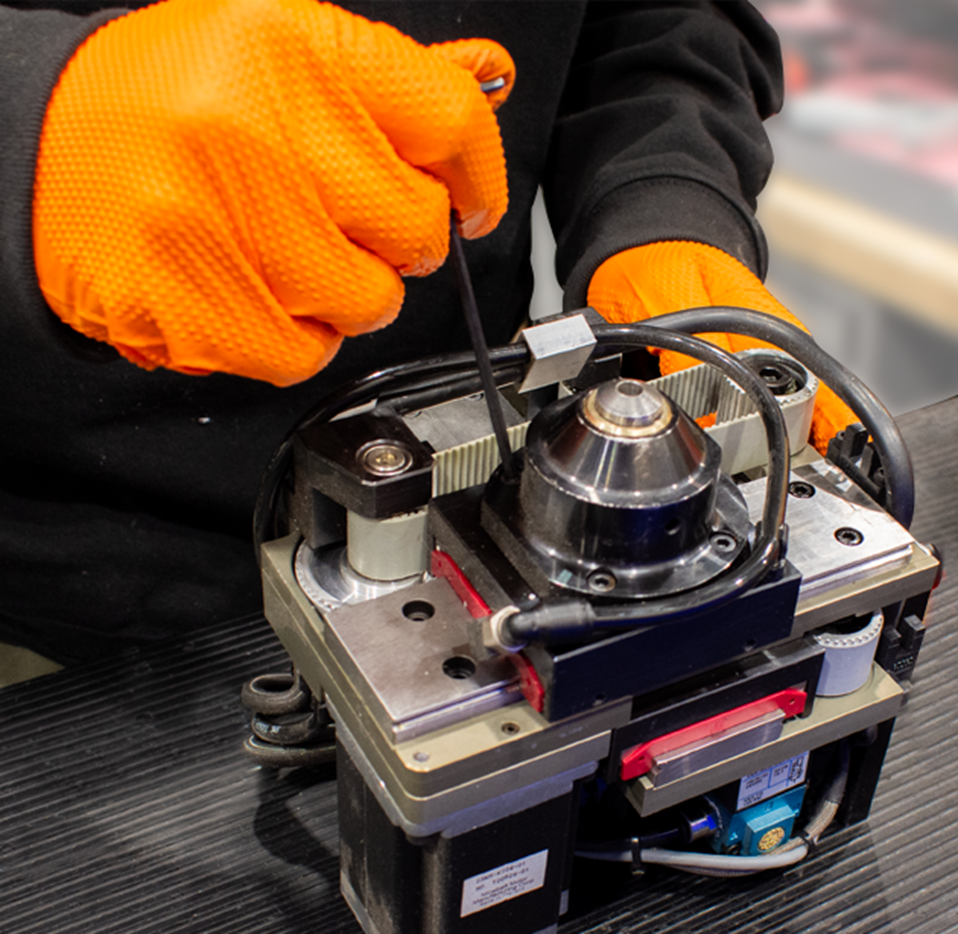

- Remove the pneumatic head and clean the stylus, spring, and cylinder on a regular schedule depending on your environment.

- Resharpen the stylus point periodically, especially if marking hardened materials like steel. A dull tip leads to poor mark quality and stress on the machine.

- Replace worn or broken parts immediately to ensure top performance.

Sample Routine Maintenance Schedule for Your Dot Peen Marking Machine

While maintenance schedules may differ based on your environment, machine type, and materials being marked, here is a recommended maintenance guide for your dot peen marking machine:

Weekly:

- Visually inspect cables and connectors

- Check air line

- Clean any visible dust or debris

Monthly:

- Lubricate piston rings and springs

- Clean photocells and stylus

- Inspect stylus wear and alignment

Quarterly:

- Full physical inspection of internal components

- Inspect controller

MECCO includes a maintenance guide with all of our dot peen marking machines to help customers stay on schedule.

Did you Know?

MECCO customers have access to a convenient resource library where you can find guides, engineering drawings, and other helpful documents. To get up and running quickly or troubleshoot any issues with your pin marking machines, browse our Virtual Product Support.

Know the Signs of Trouble

Your machine might need attention if you notice any of the following warning signs:

- Marks appear shallow or have poor quality

- The pin won’t fire

- The machine clicks but won’t power on

- “0 Position Error” shows up, meaning the head isn’t returning to home after marking.

Before sending the unit in for repair, check that the piston rings are lubricated, the marking cable is undamaged, and the photocells are clean. If those all look good, the issue may lie in the controller or motor, at which point it’s best to contact MECCO for service.

How Long Can a Dot Peen Marking Machine Last?

With proper maintenance, MECCO dot peen machines can last over 30 years. In fact, many of our customers are still using machines from the 1990s. The key is prevention – keep the system clean, pay attention to wear and tear, and keep up with your maintenance schedule.

MECCO’s Maintenance Support

MECCO offers a full suite of tools to help customers maintain their dot peen systems, including:

- 2-year warranty covering parts and labor

- Customer success plans for proactive maintenance

- Onsite and virtual training to instruct operators on best practices

- Remote support, troubleshooting guides, and digital tools available upon request

- Our service and sales teams can also conduct onsite visits to review equipment condition and provide maintenance recommendations.

Remember, don’t wait for a problem to arise. If you build regular maintenance into your schedule, you can get decades of consistent performance from your dot peen machine.

Contact MECCO today to explore our full line of pin marking machines or inquire about maintenance plans.