Laser Marking and Engraving Applications

About Laser Marking and Engraving

Laser marking applications involve permanent industrial processes that use a beam of concentrated light to alter the surface of a part. The term "laser marking" actually represents several types of laser applications, including laser engraving.Laser marking and engraving applications vary widely and are used across a variety of industries and materials. Laser applications like marking, etching, engraving, and carbon migration allow manufacturers to create important identifying marks on their products, including barcodes, QR codes, serial numbers, date codes, and more. Laser technology can also be used for a wide range of processes, such as bonding, welding, and cutting. These automated marking technologies save time, reduce waste, and can enable part traceability -- a critical element of Industry 4.0.

Types of laser marking applications include:

Laser Marking

Laser Etching and Engraving

Laser Annealing

Laser Bonding

Laser Cutting

Laser Discoloration

Laser Welding

Laser Ablation

Benefits of Laser Part Marking

Laser part marking technology is growing in popularity among many manufacturers thanks to its numerous operational advantages.While there are several different types of laser processes, they share many similar benefits, including:

- Permanent and readable marks

- High-speed operations

- High-contrast marks

- No contact

- Minimal consumables

- Marks metals, plastics, rubber, paper/cardboard

Laser Part Marking and Traceability

Part traceability, the capacity for tracking a component and its relevant history throughout its life cycle, is more important than ever in today’s industrial environment.

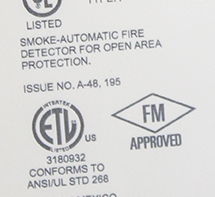

The growing complexity of supply chains in addition to the threats of counterfeiting and product recalls have prompted many modern manufacturing operations to implement high-quality permanent laser part marking systems. These systems are able to link unique identifiers – such as 1D linear barcodes or 2D matrix codes – to a computer-enabled database via MECCO’s EtherMark technology or custom graphical user interfaces (GUIs).

The marked codes can provide invaluable track and trace information, such as part number, lot number, and manufacturing date.

Text on black plastic, Logo on wood, Graphics on anodized aluminum, Layer removal on cardboard, 2D Data Matrix on metal, Contrast mark on white plastic

Laser Marking and Engraving Various Materials

- Steel and stainless steel

- Bare and cast aluminum

- Copper

- Titanium

- Plastics

- And many more materials

Laser Marking on Metals

Laser Marking on Plastics

Laser Marking on Organic Materials

Laser Marking Applications in Manufacturing

Lasers have many valuable uses in today's manufacturing business. Explore the different laser applications, then learn more details, understand when to use each application, and explore videos to see them in action.

Laser Annealing

Laser Bonding

Laser Cutting

Laser Discoloration

Laser Etching and Engraving

Laser Marking

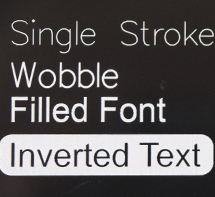

Laser marking is a permanent process that leaves a lasting mark on a surface through a variety of methods. This marking can be done with a pulsed or continuous wave laser to add barcodes, unique identification numbers, and other valuable traceability information.

Learn More about Laser Marking

Laser Welding

Laser Ablation

Get the Right Mark with Laser Application Testing

Getting the right mark consistently is important for any successful operation. A variety of factors, from materials to finishes can affect your final outcome.

Before making an investment, take advantage of our free sample marking, available through our state-of-the-art applications lab. Our experts work with you to ensure you are getting the right mark every time, helping you reduce waste, increase quality, and save money.

MECCO: Innovating Marking & Traceability for Manufacturers

Your business isn't one size fits all, and your marking solution shouldn't be either.

Across our long history of innovation, the MECCO team has lived by this philosophy: First, understand what our customers need. Then, provide the highest possible quality marking and traceability solutions to help them meet their goals. As a leading laser part marking manufacturer, we offer a full line of laser marking systems and engineered solutions. Through the MECCO Experience, our experts guide you to the best solution to help you be more efficient, more productive, and more competitive in an ever-evolving market.

Contact us today to learn how we can help you with your traceability needs.

Watch MECCO Lasers

See these marking applications in action in the MECCO Video Library, where our lasers demonstrate the marking of barcodes, text and logos on a variety of materials.

Explore Our Machines

Explore our variety of laser marking products, from OEM models to benchtop workstations to full turnkey solutions. Our product section allows you to filter by material, application, industry, and part size to find the best piece of marking equipment for your project.