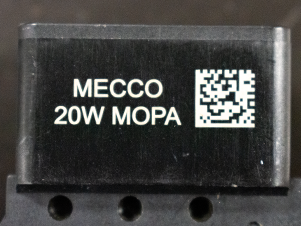

SMARTmark® VP MOPA Fiber Laser Marking System

Models: 20W, 100W, 200W

A MOPA Fiber Laser Marker that Goes Further

Choose a fiber laser engraver that goes further with the SMARTmark® VP MOPA Fiber Laser Marking Machine from MECCO. The latest addition to the industry’s largest line of industrial laser marking solutions, the VP MOPA Fiber Laser delivers the highest level of flexibility and control thanks to variable pulse MOPA technology.

With the ability to adjust the laser’s pulse width, automotive, medical device, and other manufacturers will see results beyond what a traditional fiber laser marking machine can offer for a wide range of applications. The advantages include higher contrast on plastics, faster deep engraving marks on metal, and clean black marks on clear anodized aluminum.

Sample Mark Gallery

MECCO is known for the high quality of the marks we produce, and these samples from SMARTmark VP MOPA Fiber Lasers showcase some of the common applications that highlight its capabilities. Fiber lasers can be used for a wide variety of applications, from industrial traceability to branding, on materials such as steel, copper, aluminum, plastic, ceramic, and brass.

Watch videos of the Fiber Laser marking machine.

Higher Contrast on Plastics

Achieve higher contrast on plastic materials for applications such as day & night marking. Avoid burning and excess foaming when engraving plastics thanks to the ability to control the amount of heat directed at the material’s surface with a variable pulse MOPA laser.

Faster Deep Engraving on Metals

Black Marking on Clear Anodized Aluminum

Achieve black marking on clear anodized aluminum, from cell phones and electrical panels to automotive trim.

Request Sample Marking

Don’t see what you’re looking for? To help you find the right marking equipment for your project, MECCO offers free sample marking so that you can see what the mark would look like on your material.

VP MOPA Fiber Laser Marking System Features

- Marks widest variety of materials, including steel, titanium, aluminum, copper, ceramics & some plastics

- 100,000+ hours of laser life, reducing costs and production downtime

- Small 19" rack mount footprint makes it easy to integrate with other equipment and existing assembly lines

- 111.1mm square mark field (other sizes available)

- No consumables and minimal maintenance help reduce operating costs

- Mount laser in any orientation

- Air-cooled 20W-200W models

- Real-time visible live pointer for previewing your mark

- Higher beam quality than flash lamp, diode pumped and vanadate, resulting in a high quality mark

- Integrated safety shutter

- Also available in 2.5D configuration

- 2-Year equipment warranty -- parts and labor

- Laser Customer Success Plans available for preventative maintenance

Advanced Features for Integrators:

- LEC embedded controller allows for stand-alone mode operation without a PC

- Dual E-Stop channels

- Dual door interlock channels

- Enhanced diagnostics with LCD Display to notify operator/PLC of system status

- RS-232 and Ethernet TCP/IP Communication

- Remote and COM Interface for dynamic and external control of the laser

- EtherNet/IP & Modbus or Profibus Communication

System Technical Specifications

|

Laser Source |

Fiber, Ytterbium, Variable Pulse Width |

|

Output Power |

20W, 100W, or 200W |

|

Peak Power |

31.3 kW |

|

Power Requirements |

110/220 VAC, 10A, 50/60Hz |

|

Wavelength |

1064nm |

|

M2 |

<1.2 |

|

Operation Mode |

Pulsed with Pulse Width Adjustment |

|

Pulse Rep Rate |

1-4000 kHz depending on model |

|

Cooling |

Air |

|

Scanning Method |

XY Galvanometer |

|

Rail Weight |

20W-100W: 20 lbs |

|

Rail Dimensions |

20W-100W: 19.736” x 5.188” x 4.961” |

|

Cable Length |

20W-100W: 9.8' |

|

Controller Dimensions |

20W: 19.49” x 5.17” x 18.99” |

|

Accuracy |

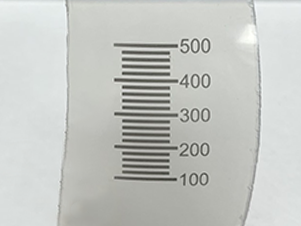

3.5 μm across field |

|

Max Line Speed |

2,500 mm/sec using 160mm lens |

|

Controls |

Industrial LEC-embedded laser marking controller |

|

Communications |

Ethernet TCP/IP, EtherNet/IP™, PROFINET, Modbus TCP, RS232 |

|

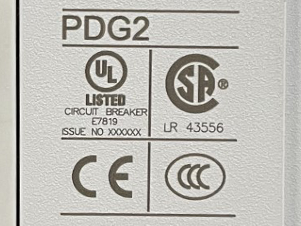

Approvals |

CE |

|

Warranty |

2 Years |

|

Documentation |

USB Flashdrive with Operator’s Manual & Integration Guide |

Lens Options

20W Lens Options

|

Lens |

Marking Field |

Working Distance |

|---|---|---|

|

160mm |

111.1mm x 111.1mm (4.4” x 4.4”) |

182mm (7.17”) |

|

254mm |

177.1mm x 177.1mm (6.97” x 6.97”) |

299mm (11.77”) |

|

330mm |

230mm x 230mm (9.1” x 9.1”) |

385mm (15.16”) |

|

420mm |

336mm x 336mm (13.2” x 13.2”) |

491mm (19.33”) |

100W-200W Lens Options

|

Lens |

Marking Field |

Focal Length |

|---|---|---|

|

163mm |

112mm x 112mm (4.4” x 4.4”) |

203.8mm (8.02”) |

|

254mm |

160mm x 160mm (6.3” x 6.3”) |

304.7mm (12.0”) |

|

350mm |

220mm x 220mm (8.6” x 8.6”) |

409.0mm (16.1”) |

|

450mm |

320mm x 320mm (12.6” x 12.6”) |

516.0mm (20.31”) |

Laser Marking Software

SMARTmark lasers all use WinLase® laser marking software with unique MECCO options configured to your needs.

We also offer custom Graphical User Interfaces to help ensure that ease-of-use, automation, database integration and vision inspection meet the needs of your project.

SMARTmark VP MOPA Fiber Product Resources

-

-

Software Files

-

Manuals

-

Integration Guides

-

Engineering Drawings

-

Troubleshooting Videos

-

Software Training Videos

-

Go To Downloads

Laser Product Options

-

OEM Models

An OEM is the core product for making traceability marks on your parts. It consists of the laser rail with controller and is the choice for machine builders to integrate marking into a larger turnkey solution. -

Enclosures & Workstations

Lasers can be added to standalone, configurable enclosures that are designed to meet CDRH Class 1 safety regulations and available in a range of sizes to meet the requirements of your parts. Learn more about the LightWriterTM and LightWriter PRO Connect series. -

Custom & Configured Solutions

SMARTmark® Laser Marking Systems are configurable to your part and process automation requirements. With our Custom and Configured Laser Solutions, we can design and manufacture an enclosure to meet your needs in part handling, vision, software, and database integration.