Blog

In today’s competitive manufacturing environment, efficiency matters. The pressure to cut costs without sacrificing quality is constant, whether you're producing automotive parts, medical devices, electronics, or consumer goods. One technology helping manufacturers meet this challenge head-on is laser marking, and MECCO is leading the way with systems that boost performance while delivering measurable savings.

Lowering the Total Cost of Ownership

Traditional marking methods like inkjet, dot peen, and labeling systems come with ongoing costs – inks, solvents, labels, tool wear, and maintenance. Laser marking eliminates nearly all of these. In high-volume operations, laser marking can cost as little as $0.02 per mark, compared to $0.07 or more with other technologies.

Time Is Money: Laser Marking Streamlines Workflows

Laser marking doesn’t just reduce material expenses – it improves operational efficiency with:

-

Faster Setup, Less Downtime: Digitally controlled lasers eliminate manual retooling. Operators can switch between jobs with a few clicks, cutting setup times dramatically. Advanced systems with vision alignment further reduce human error and setup complexity.

-

Seamless Automation: MECCO’s custom software integrations enable laser systems to pull data directly from your existing manufacturing infrastructure. This minimizes manual input, eliminates mislabeling, and increases throughput.

-

Minimal Maintenance: Unlike inkjets or mechanical markers, laser systems require little upkeep. With no consumables or moving parts touching surfaces, downtime due to maintenance is drastically reduced.

Laser marking’s ability to streamline these processes saves both time and labor, making it a go-to choice for modern manufacturing. In high-volume settings like automotive and aerospace, manufacturers report setup times dropping from hours to seconds, with nearly instant mark application, meaning higher throughput and lower labor costs.

5 Ways Laser Marking Cuts Operational Costs:

-

Reduced Retooling Time: Traditional marking methods require physical tool changes for each design. Laser marking is fully digital, so you can switch between designs instantly just by updating the software, with no mechanical adjustments needed.

-

Faster Part Setup: Position the part and start marking – no need for punch alignment, ink prep, or manual calibration. Some MECCO systems even use vision technology to auto-align parts, saving more time.

-

Eliminate Manual Steps: Manual processes like applying ink, cleaning tools, or adjusting pressure slow things down. Laser marking is non-contact and fully automated, keeping operators focused on production.

-

High-Speed Marking With Automation: Lasers mark in seconds and easily integrate into production lines, removing bottlenecks and boosting throughput.

-

Material Versatility: Lasers can mark metals, plastics, ceramics, and more without changing tools. This avoids the delays of reconfiguring equipment for different materials or part types, making them ideal for mixed-material production environments.

Learn more: Laser Matierials Chart

Precision That Prevents Costly Errors and Compliance Failures

Rework, recalls, and compliance violations are costly. Laser marking helps avoid these by producing permanent, high-resolution marks that remain legible under harsh conditions — heat, abrasion, chemicals, and more. Whether it's serialized barcodes or unique identifiers (UIDs), laser marks support:

-

Regulatory compliance in industries like medical devices and aerospace

-

Reduced product recalls from missing or unreadable labels

-

Fewer labeling errors and associated rework

Laser marking provides traceability and accuracy you can count on — saving time, reducing waste, and protecting your bottom line. This level of reliability is critical in sectors like automotive, aerospace, and medical devices, where regulatory bodies and customers alike require traceability.

Case in Point: Ford Motor Company

Ford partnered with MECCO to replace its ink and dot peen marking systems. The results were clear when Ford evaluated MECCO laser systems against traditional marking methods – the comprehensive cost analysis showed MECCO’s laser marking solution would eliminate consumable expenses, reduce manual labor, improve traceability, marking quality, and speed, and integrate seamlessly into automated lines, delivering a faster, cleaner, more cost-effective solution. The laser marking system paid for itself in under a year – plus enhanced compliance, cleaner marks, and quicker processes.

Built for Efficiency, Designed to Scale

MECCO systems are built to save costs and scale with your operation:

-

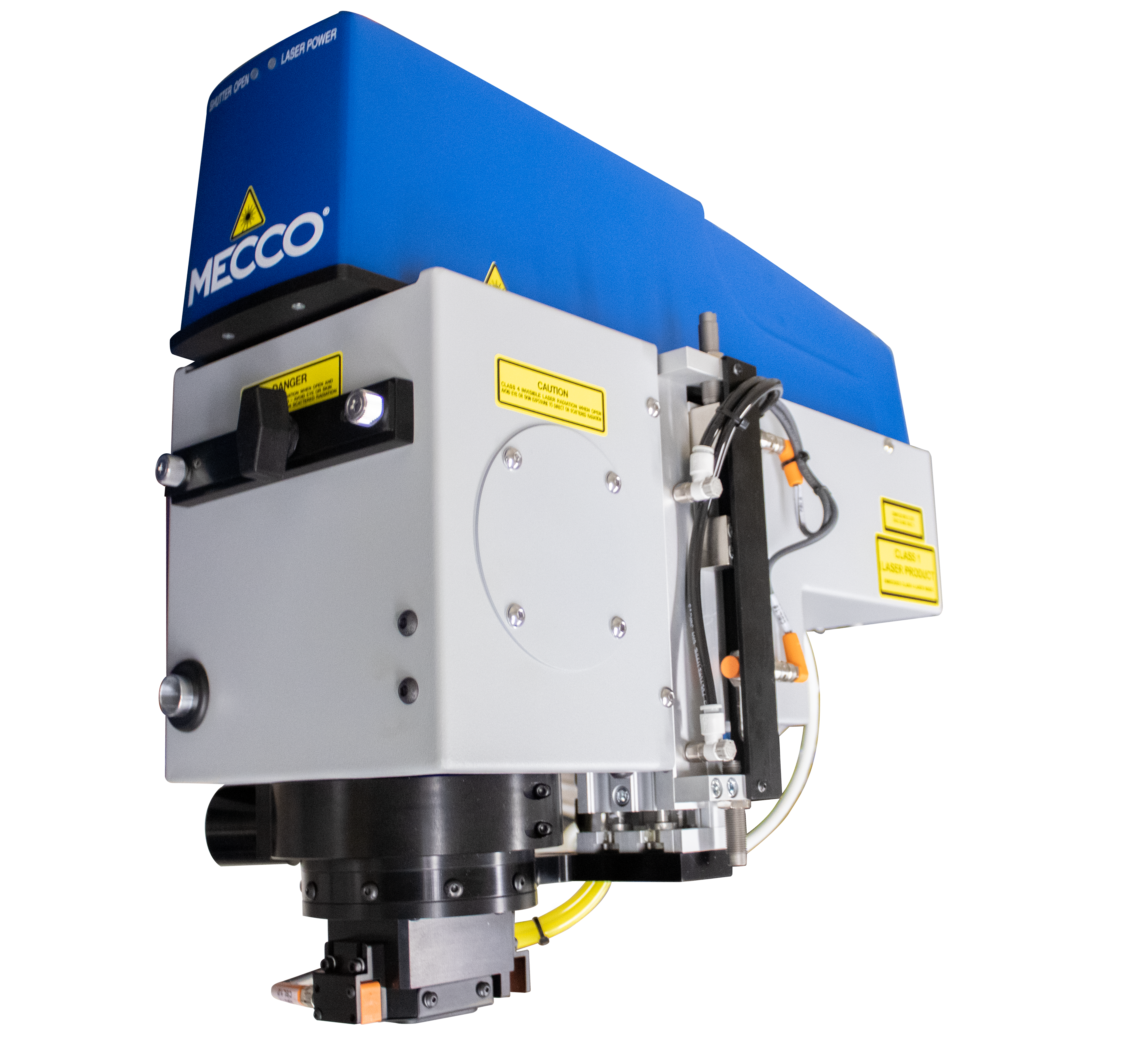

LightWriter™ Laser Marking Workstations: Compact, Class I certified, and energy-efficient — ideal for small to mid-size production environments.

-

Turnkey Laser Solutions: From simple part marking to fully automated inline systems, MECCO customizes solutions that evolve with your growth.

-

Custom Software Integration: Our in-house-developed software and controller tech provide fast, intuitive interfaces and seamless data connectivity – outpacing competitors who rely on off-the-shelf platforms.

MECCO offers turnkey and modular systems and industry-leading support to help manufacturers grow without increasing overhead.

Watch and learn more about MECCO’s Custom Turnkey laser marking systems.

A Smarter Investment for Sustainable Savings

Modern manufacturing demands more than precision — it demands efficiency. MECCO helps manufacturers:

-

Eliminate consumables and reduce maintenance costs

-

Increase uptime with automated workflows

-

Maintain compliance with permanent precision

-

Scale marking capabilities as operations grow

With decades of experience and a customer-first approach to innovation, MECCO is the trusted partner for manufacturers looking to reduce costs and future-proof their operations, one mark at a time.

Future-Ready Laser Marking: Innovations That Lower Costs

MECCO is already engineering the next wave of laser marking innovations, including:

-

Energy-efficient fiber and UV lasers that lower electricity use

-

Portable, compact systems for flexible deployment in multiple production areas

-

3D and multi-axis marking to handle complex part geometries in one pass

-

IoT-enabled systems for real-time tracking, remote monitoring, and performance optimization

Laser marking is more than a process — it’s a cost-saving, efficiency-boosting strategy. With MECCO’s advanced systems, you don’t just keep up with the future — you help shape it. If you're ready to reduce consumables, eliminate downtime, meet compliance standards, and future-proof your production line, MECCO has the laser marking solution to fit your needs.