Marking Solutions for the Aerospace Industry

Marking Solutions for the Aerospace Industry

These machines have proven to be beneficial for aerospace and defense companies by saving time and reducing costs, thereby minimizing recall durations and associated profit losses. MECCO’s technology has successfully added traceable markings to various aircraft, including helicopters, airplanes, and rockets, serving some of the leading firms in the aeronautics industry.

Why Choose MECCO?

- Industry-Leading Precision: Achieve the fastest, most durable marks on parts on pieces designed for air and space travel.

- Seamless Integration: Compact, versatile systems designed to fit effortlessly into existing manufacturing floors.

- Unparalleled Support: Our expert service team ensures uptime, providing rapid response and maintenance to keep your operations running smoothly.

- Regulatory Compliance: Meets requirements under Electronic Code of Federal Regulations Part 45, ODVA membership, and CE certification for global traceability requirements.

Typical Marking Applications

MECCO’s portfolio of laser and dot peen technology supports a wide range of Aerospace applications, delivering permanent marks on diverse materials. Key applications include:

- DoD Regulatory Engraving: Creates marking that complies with marking requirement document MIL-STD-130.

- Data Matrix Codes: AIM DPM 2D codes on materials for cradle-to-grave tracking

- Track and Trace Marks: Serial and batch numbers on casting and forgings for supply chain efficiency

Common Aerospace Materials

Our systems excel at marking the most common aerospace materials, ensuring durability and legibility for traceability, assembly, and maintenance. Key materials include:

- Steel and Stainless Steel: For frames and other structural components

- Aluminum and Anodized Aluminum: Fuselages, wings, fuel tanks, and other machined components

- Titanium Alloys: Engine components and structural parts

- Ceramics: High-temperature components

- Composite Materials: Windows, sensors, structural pieces, etc.

Automotive Industry Certifications

MECCO’s solutions are engineered to meet rigorous industry standards:

- AIAG Compliance: Follows Electronic Code of Federal Regulations Part 45 – Identification and Registration Marking, Title 14: Aeronautics and Space

- ODVA Membership: Ensuring compatibility with automotive automation protocols.

- CE Certified: Meeting global safety and performance requirements.

Learn more about MECCO’s certifications.

Marking Solutions for Automotive

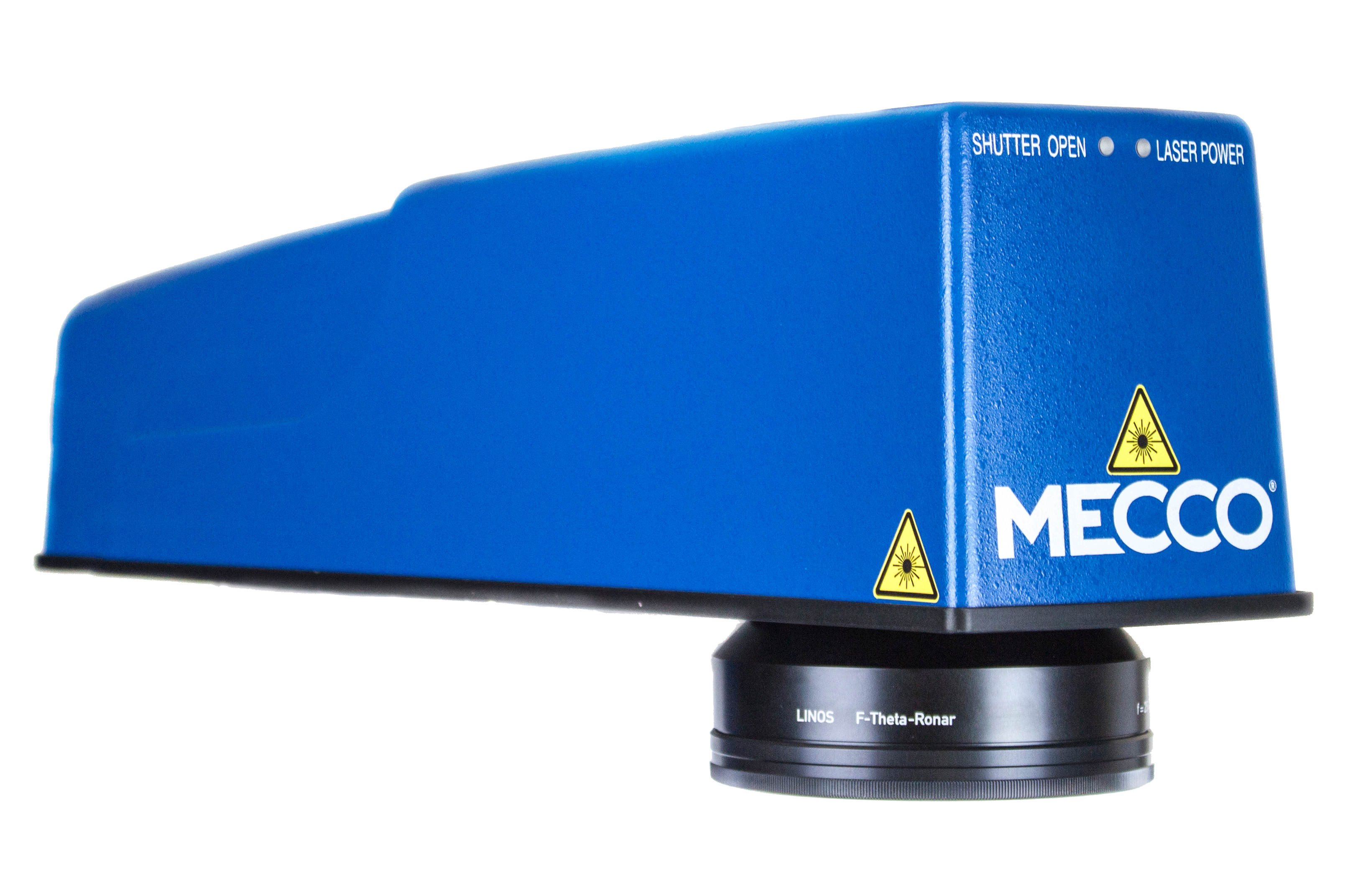

SMARTmark® OEM Fiber Laser Marking Machine

The SMARTmark® Fiber Laser stands at the forefront of aerospace marking technology. This advanced system produces deep, permanent engravings with exceptional speed and pinpoint precision, making it ideal for marking serial numbers, Data Matrix codes, and identifiers on various materials, including metals and plastics. Its capabilities are particularly well-suited for critical aerospace components, such as those found in jet engines, avionics, and other crucial equipment that ensures safe and efficient flight operations.

Learn More about the SMARTmark® Fiber Laser Marking Machine

SuperFast Dot Peen Marking System

Our Scribing Machines are vital for the aerospace industry, delivering high-quality permanent marks that meet strict standards. The Couth SuperFast, an advanced dot peen marker using Vibra Peen™ technology, pulses the pin 80 times per second for precise character tracing and marks comparable to engraving quality. This efficiency allows aerospace manufacturers to achieve superior marking in half the time. Additionally, dot peen marking avoids a heat-affected zone, preserving the integrity of high-stress components. With our technology, manufacturers can confidently mark critical parts, ensuring compliance, traceability, and enhanced quality and safety.

Learn more about SuperFast Marking

LightWriter Class IV Marking System

Mark large aerospace components safely and efficiently with the LightWriter Class IV Marking System. Designed specifically for the aerospace industry, it offers modular design, user-friendly software, and cost-effective operation, making laser marking easier and more economical. The LightWriter seamlessly integrates into your existing database and is straightforward for operators to learn and use. Optimize your aerospace marking process with this advanced solution.

Learn more about the LightWriter™

Success Story

When part-marking inefficiencies began to affect customer relations and production costs, Honeywell Aerospace in Tempe, Ariz., transitioned to a new fiber laser marking system. In 2014, the facility faced quality issues, bottlenecks, rework, and customer returns linked to marking serial and part numbers on products. The ISC Engineering and Production Quality team identified key challenges, including the need for better integration with SAP, automation of manual tasks, and improved inspections.

To address these challenges, Honeywell partnered with the MECCO team, which implemented a "total traceability solution" using the SMARTmark system. This integration reduced human errors, automated workflow, and improved inspections with 100 percent in-machine verification. Marking-related quality issues, previously costing $2,500 each, decreased significantly. Furthermore, the new 20-watt SMARTmark Fiber Laser System minimized the required floor space by half.

|

Our machines add traceability to parts of all shapes and sizes on aerospace machines of every type. From the largest metal parts to the smallest, most delicate electronic components, we have a solution for your application.

MECCO machines ensure permanent traceability per the Electronic Code of Regulations Part 45 to ensure sure full FAA compliance.

If any of our systems do not fit your exact needs, we can custom engineer a solution to the exact specifications your project requires.

We have worked with some of biggest players in the aerospace industry to create and design customized laser and pin marking applications that fit their exact needs. Have a problem? We have a solution. The easiest way to integrate laser marking or dot peen marking into your manufacturing processes is with our native EtherNet/IP communication solution, EtherMark, and the space-saving, patented Safety Seal.

Made for marking large parts, the Safety Seal has delivered security, cost-effectiveness and process control in some of the most high-volume automotive plants in the United States. |

Request a Quote

Integrating a Total Traceability Solution

CASE STUDY: Honeywell Aerospace

When part-marking inefficiencies began to inflate production costs, this aerospace components manufacturer transitioned to a new laser marking system in order to successfully overcome five big challenges.

MECCO RESOURCES

We're used to tackling manufacturers' challenges across various industries. Take a look at some of the systems we've built to help streamline marking and traceability.

Latest News

-

How to Maintain Your Dot Peen Marking Machine for a Longer Life

Read MoreDot peen marking machines are typically considered durable and built to last. Regular maintenance is essential for extending its l...

-

How Laser Marking Reduces Operational Costs for Manufacturers

Read MoreIn today’s competitive manufacturing environment, efficiency matters. One technology helping manufacturers meet this challenge hea...