Marking Solutions for the Electronics Industry

Permanent Identification for Your Electronic Components

Why Choose MECCO?

- Production automation: Items, products, and parts can be tracked and traced inside the facility during manufacturing.

- Mark Small Areas: With SMARTmark® and LightWriter™ Lasers, you can mark small areas on circuit chips or other small components. Add traceability to even your smallest parts with 2D Data Matrix barcodes.

- High Quality, Contrast Marks: Poor mark quality interferes with your operation and products. Laser marking systems make clear marks that have contrast without creating electrical interference by exposing the copper.

- Anti-counterfeiting: Serial numbers and scannable codes can be tracked in a database to ensure product authenticity.

Typical Marking Applications

MECCO’s portfolio of laser and dot peen technology supports a wide range of electronic applications, delivering permanent marks on diverse materials. Key applications include:- Molded Plastic Housing

- Meter Housings

- Connectors

- PLCs

- Printed Circuit Boards (PCBs)

- Plastic Electrical Breakers

Common Electronic Component Materials

Our systems excel at marking the most common automotive materials, ensuring durability and legibility for traceability, assembly, and maintenance. Key materials include:

- Silicon: Used in SCBs and PCBs

- Copper: Used for wiring and circuit board traces

- Gold: Connectors, contacts, and other conductive applications where corrosion resistance is needed

- Aluminum: Used in powerlines and other applications

- Plastics and Polymers: Used for product housing

- Ceramics: Used in capacitors, substrates, and other electronic applications

Electronic Industry Certifications

MECCO’s solutions are engineered to meet rigorous industry standards:

- ODVA Membership: Ensuring compatibility with automotive automation protocols.

- CE Certified: Meeting global safety and performance requirements. Learn more about MECCO’s certifications.

Premier Marking Solutions for Electronic Components

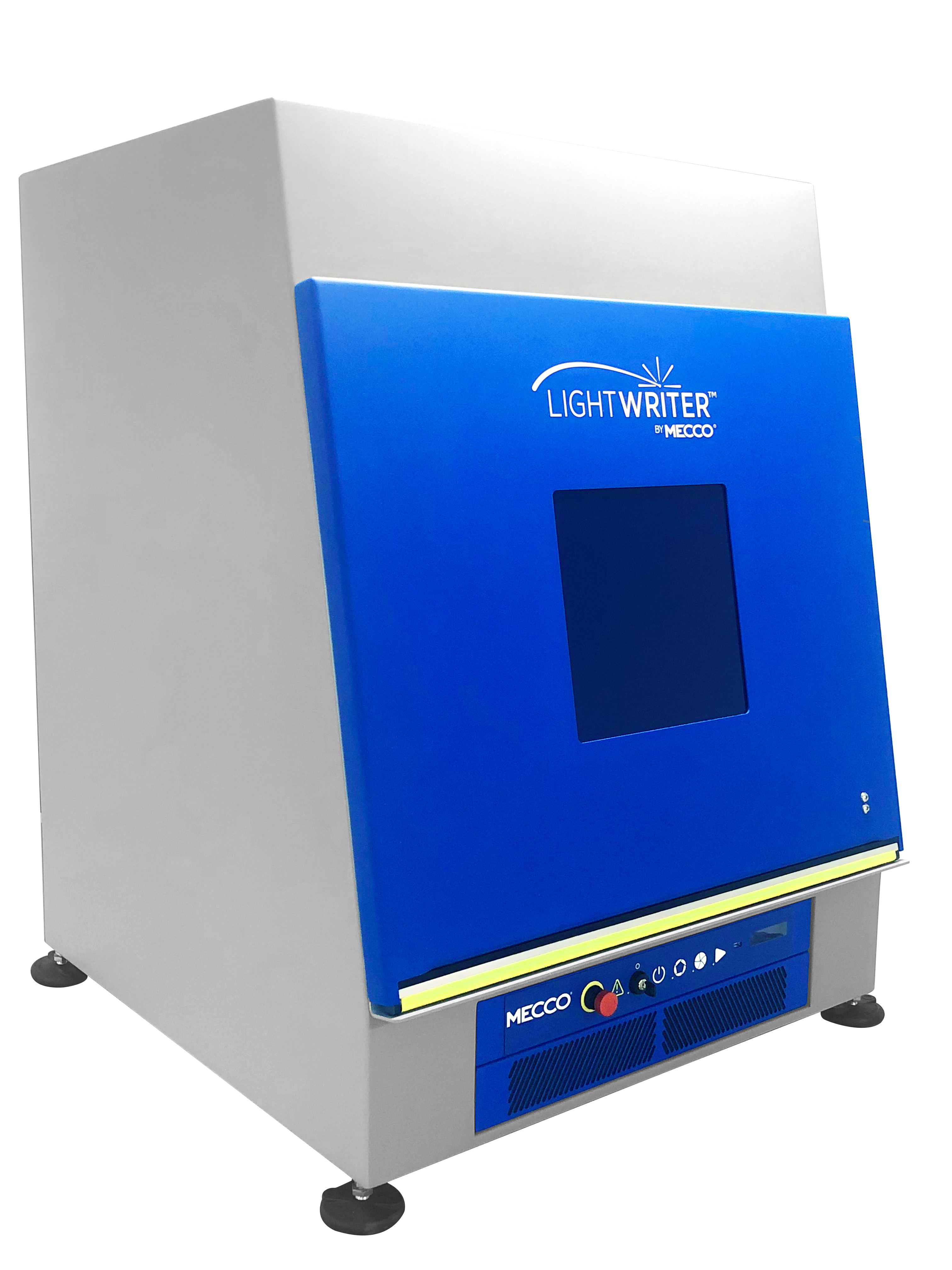

LightWriter ™ Laser Marking Enclosures

The LightWriter™ Series is a line of complete industrial laser engraving enclosures and Class IV systems designed for modern manufacturing. These versatile, all-in-one systems accommodate various materials and part sizes, featuring a sturdy Class 1 enclosure for safety. This system is easy to use and can mark metal or plastic housings and is already being used to prevent counterfeiting and gray markets.

Learn more about the LightWriter™

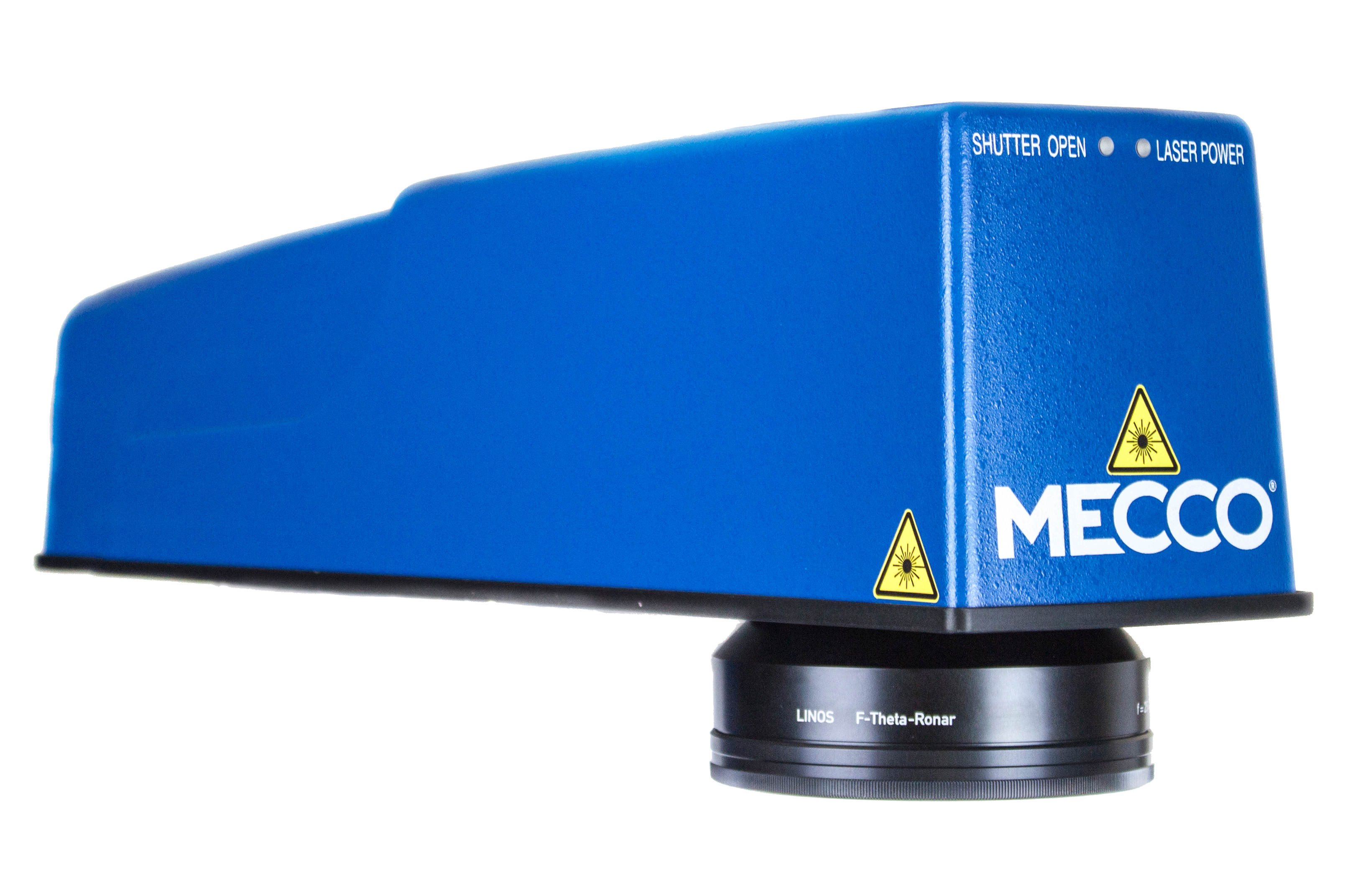

SMARTmark® OEM Fiber Laser Marker

Learn More about the SMARTmark® Fiber Laser Marking Machine

SMARTmark® UV Laser

Achieve flawless results on plastics, glass, ceramics, and other heat-sensitive materials with the SMARTmark 5W UV Laser marking Machine. Its "cold marking" technology uses a 355nm UV laser wavelength to reduce heat stress and prevent product damage. Various industries benefit from this versatile UV laser technology, providing smooth, precise marks for medical device manufacturers and allowing electronics and automotive companies to mark small, delicate components like circuit boards with minimal waste.

Learn More about SMARTmark® UV Laser Marking Machine

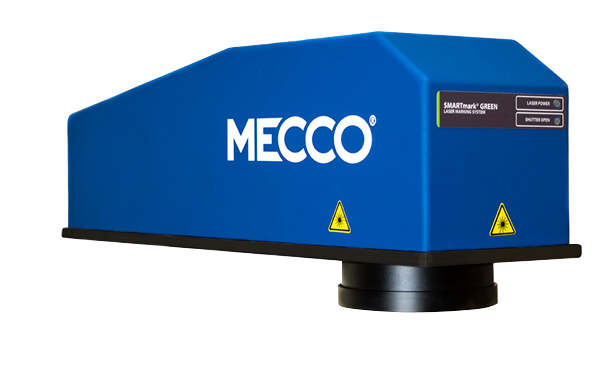

SMARTmark® Green Laser

MECCO's 20W SMARTmark® Green Laser marking machine offers high-contrast, permanent marks without distorting materials. It features a higher power output than similar "cold" lasers and a wavelength of 532nm, enabling faster marking with less heat. This makes it suitable for thin metals and heat-sensitive materials like glass, film, plastics, and silicon circuit boards.

Learn More about SMARTmark® Green Laser Marking Machine

Success Story

In the commercial and industrial electronics market, even minor manufacturing missteps can lead to costly repairs and serious consequences. A multinational electrical-equipment manufacturer recognized the threat posed by gray-market and counterfeit products and has shifted to a proactive strategy to combat these issues. This initiative is powered by a collaboration with MECCO and iTRACE Technologies, creating advances in the commercial and industrial electronics market, even minor manufacturing missteps can lead to costly repairs and serious consequences.

This preemptive strategy has already shown significant results, reducing gray-market diversions and fraud. By embracing this innovative approach, the manufacturer is better equipped to safeguard revenue and minimize risks associated with counterfeiting and warranty claims. The success stems from the collaboration among the manufacturer, MECCO, and iTRACE Technologies, achieving a new level of flexibility and control.

Permanent Alternative to Inkjet & LabelingLaser marking eliminates consumables to save money. Permanent branding and identification, plus features to increase mark accuracy can help operations avoid the over $1M in losses per year from label printing errors*.

*Institute for Supply Management High Quality, Contrast MarksPoor mark quality interferes with your operation and products. Laser marking systems make clear marks that have contrast without creating electrical interference by exposing the copper.

Make Your Mark in Small AreasWith SMARTmark and LightWriter Lasers, you can mark in small areas on circuit chips or other small components. Add traceability to even your smallest parts with 2D Data Matrix barcodes.

|

Request a Quote

CASE STUDY: Disrupting Counterfeiting

with Innovative, Tamper-Proof Laser Marking

In the commercial and industrial electronics market, the smallest misstep in manufacturing or testing can mean costly repairs, property damage, and even serious injury or death.

Aware that its reputation is on the line with every circuit breaker sold, a multinational electrical-equipment manufacturer has for years channeled substantial resources into fighting gray-market and counterfeit products, often via litigation. Recently the company adopted a preemptive strategy based on making counterfeiting more difficult and illicit supply chains easier to trace.

MECCO RESOURCES

We're used to tackling manufacturers' challenges across various industries. Take a look at some of the systems we've built to help streamline marking and traceability.

Latest News

-

How to Maintain Your Dot Peen Marking Machine for a Longer Life

Read MoreDot peen marking machines are typically considered durable and built to last. Regular maintenance is essential for extending its l...

-

How Laser Marking Reduces Operational Costs for Manufacturers

Read MoreIn today’s competitive manufacturing environment, efficiency matters. One technology helping manufacturers meet this challenge hea...